Pipe conveyor collapse refers to the situation where the conveyor belt loses its circular cross-sectional shape during material transport,becoming flat or partially flat.This causes uneven distribution of contact force between the conveyor belt and rollers,leading to issues like belt twisting and misalignment.The severity of collapse is generally categorized into three levels:mild,moderate,and severe.Mild collapse does not affect overall transport and is acceptable;moderate collapse slows down the transport efficiency but can continue to be used with caution;severe collapse renders the belt unusable and requires immediate attention.The exact degree of collapse needs to be determined based on the on-site situation.

Collapse reduces the transport space,increasing resistance and decreasing efficiency.The reduced space also increases friction between the belt and the material,raising the risk of equipment damage.Additionally,collapse can cause material leakage,resulting in environmental pollution and material loss.

Collapse commonly occurs at convex arc sections due to complex forces,leading to insufficient tension or uneven material distribution.If collapse occurs in straight sections,it indicates a severe problem with the entire belt,suggesting quality or installation issues.Material loading and unloading points can also experience collapse due to concentrated forces.

Causes of Pipe Conveyor Collapse

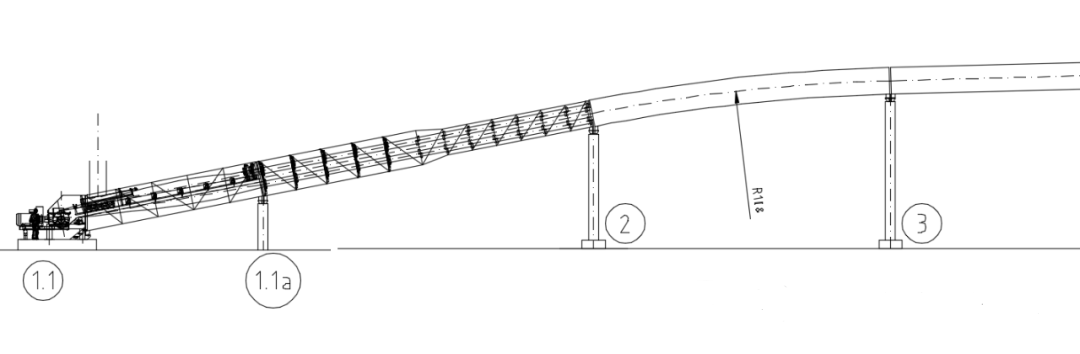

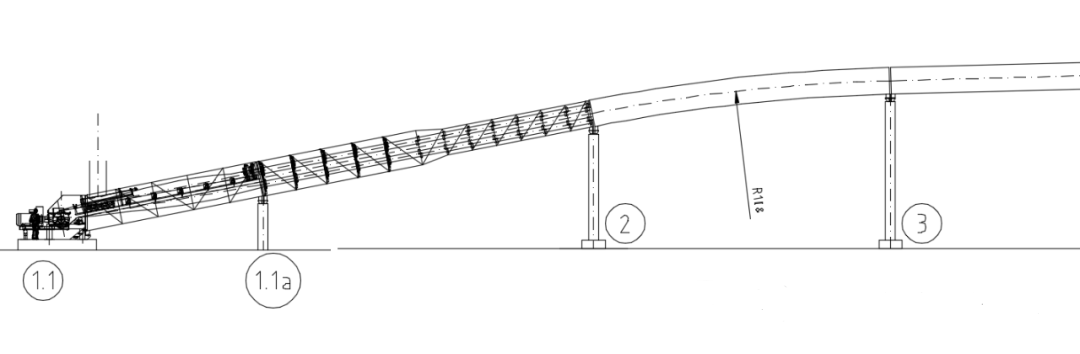

- Design Issues:Local collapse usually occurs at convex arcs with small radii,causing the belt to lose contact with the rollers.Initially,the belt is hard and maintains contact,but it softens over time,leading to collapse.Many designs use a minimum of 300 times the pipe diameter for the radius without considering actual softening during operation.

- Manufacturing Issues:Incorrect arc processing,welding deformation,or on-site manufacturing inaccuracies lead to local collapse.Cold bending of arc segments without maintaining design curvature also contributes to this problem.

- Installation Issues:Incorrect foundation height causes truss buckling,leading to local collapse.Temporary design changes or interference with existing structures during installation can also cause this issue.

- Usage Issues:Longitudinal scratches or multiple folds in the belt reduce its lateral rigidity,causing collapse.Transporting high-temperature materials can further reduce the belt's lateral rigidity.

- Belt Quality Issues:Insufficient lateral rigidity in the belt's design,combined with material fatigue over time,leads to collapse.

How to Prevent Pipe Conveyor Collapse

- Design:Optimize the convex arc radius,using the largest feasible radius to ensure good contact between the belt and rollers.Increase the transition section length to reduce edge tension.Use professional design software or discrete element analysis tools for dynamic simulation,ensuring the convex arc radius maintains contact with all six rollers.Allow extra space for adjustments,ensuring the conveyor's outer edge has enough clearance from buildings.

- Manufacturing:Strictly control the curvature of the main chord of the truss to prevent deformation after cold bending.Use auxiliary tools during welding and conduct aging treatment to maintain accuracy.Perform quality checks before delivery to ensure trusses meet design requirements.

- Installation:Verify all foundation heights before installation,ensuring smooth transitions at truss connections to avoid sharp angles.Adjust support heights as needed to ensure smooth vertical curves.

- Belt Supply:Sample test the lateral rigidity of the belt to meet design requirements.If the convex arc radius is small,increase the belt's lateral rigidity.Use high-rigidity,wear-resistant belts for long-term performance.

- Usage:Avoid prolonged exposure to sunlight by covering the truss with color boards or rain covers to prevent aging.Control the load to keep it within design limits.For high-temperature materials,control the temperature within design limits.Minimize belt scratches during operation to maintain surface integrity.

- Detection Systems:Install related detection systems for real-time monitoring and alarms,promptly addressing collapse issues.

Handling Measures and Repair Methods after Pipe Collapse

Even with comprehensive preventive measures in place, after prolonged operation—especially as the conveyor belt ages and transverse stiffness decreases—tubular belt conveyors may still experience tube collapse. Once a collapse is detected, appropriate response measures should be taken based on its severity, location, and specific cause, aiming to restore operation, minimize losses, or implement permanent repairs.

Assessing Collapse Severity and Initial Response

Mild Collapse (No Impact on Operation):

- Monitor Closely: Intensify monitoring of the collapsed area and its upstream/downstream sections using visual inspection and installed detection systems (e.g., video monitoring, tension sensors, belt misalignment switches) to track its progression.

- Adjust Load & Speed: Appropriately reduce operating load (decrease instantaneous throughput) and/or lower operating speed to lessen pressure on the belt and slow further deterioration.

- Check Tension: Recheck and adjust system tension to ensure overall tension meets requirements, particularly the tension distribution in the collapsed area.

- Clear Obstructions/Material Buildup: Inspect the vicinity of the collapse for material accumulation, spillage, or foreign object blockages and clear them immediately.

Moderate Collapse (Impairs Efficiency, Requires Cautious Operation)

- Immediate Load/Speed Reduction: Reduce load and speed operation must to prevent rapid worsening.

- On-site Diagnosis: Immediately dispatch professionals for a field inspection, focusing on:

- Exact location of collapse (convex curve? straight section? loading point?).

- Extent of collapse (a few local idler sets? or multiple consecutive sets?).

- Belt surface condition (severe abrasion, cuts, edge damage?).

- Idler condition (missing, damaged, seized rollers?).

- Truss structure (deformation, subsidence, support failure?).

- Develop a Temporary or Short-term Repair Plan: Based on findings, decide whether temporary measures can sustain operation until planned downtime or immediate shutdown for repair is necessary.

Severe Collapse (Operation Halted)

- Emergency Shutdown! Immediately stop the conveyor to prevent further damage to the belt and idlers (e.g., belt folding, tearing, idler shaft breakage).

- Safety Isolation: Ensure the area is safely isolated to prevent injury from material leakage or unexpected movement of components.

- Thorough Diagnosis & Repair Plan: Arrange a comprehensive inspection and root cause analysis to formulate a complete repair or replacement strategy.

Handling Measures for Common Causes

Decrease in Belt Transverse Stiffness

Temporary Reinforcement:

- Local Tube Reinforcement: Temporarily install simple adjustable support devices (e.g., curved steel plates, pipe-clamp style supports) between a few idler sets in the collapsed area (especially under convex curves and loading points) to gently lift the collapsed section from below and restore tube shape for interim operation until scheduled replacement. Exercise extreme caution to avoid secondary damage to the belt or causing misalignment/twisting.

- Adjust Idler Configuration: In the worst collapse zone, temporarily replace one or more sets of hexagonal tube-forming idlers with troughed idler sets featuring a greater troughing angle (if space and structure permit). This uses the V-shape to support the collapsed belt bottom but alters the original tubular operation mode, serving only as a short-term emergency measure.

Permanent Repair:

- Local Belt Replacement: If the collapse is concentrated and short (e.g., 10-20 meters), and the overall belt wear hasn't reached replacement criteria, consider cutting out and replacing that segment. The new section must match the original belt (model, strength, stiffness), requiring extremely high-quality vulcanized splicing to ensure uniform stiffness transition at the joint.

- Full Belt Replacement: This is the most fundamental and common solution, especially for severely aged belts, multiple collapse points, or overall insufficient stiffness. Key points:

- Select Suitable Belt: Mandatorily choose a belt with a higher transverse stiffness grade (clearly specify this requirement to the supplier), adequately considering material characteristics (e.g., high-temperature materials require heat-resistant belts).

- Re-evaluate Design: Utilize the replacement opportunity to re-assess the original design. Where feasible, increase the radius of convex curves in severe collapse areas. Check if tension settings need adjustment.

- Precise Installation: Ensure strict centering and uniform tensioning during new belt installation, particularly in transition zones and curve sections.

Collapse Caused by Design/Fabrication/Installation Defects:

- Insufficient Convex Curve Radius/Inaccurate Curve:

- Optimize Idler Sets: If altering the truss structure isn't feasible, consider using specially designed "reinforced rigid idler sets" in problematic convex curve sections. These sets may feature thicker shafts, sturdier frames, or internal bracing to provide stronger constraint and maintain tube shape.

- Add Skirtboard Support Plates: Install carefully designed skirtboard support plates (wear-resistant, smooth surface) below the collapse area at the loading point. These guide material toward the center and provide slight upward support for the tube shape.

- Structural Modification (Higher Cost): If collapses are frequent and severely disrupt operation, assess the feasibility of structural modifications like locally increasing the convex curve radius or modifying the truss structure. This usually involves higher costs and longer downtime.

- Truss Deformation/Incorrect Elevation/Support Failure:

- Align or Reinforce Truss: Jack up and correct subsided truss support points, and add support structures (e.g., columns, beams) for reinforcement.

- Correct Foundation/Support Elevation: Re-adjust the height of foundations or supports in problem areas to ensure a smooth, continuous line profile (especially in transitions and curves).

- Check and Tighten All Connections: Ensure all truss connection bolts, support base bolts, etc., are properly tightened.

- Idler-Related Issues:

- Replace Damaged/Missing Idlers: Immediately replace all damaged, deformed, or seized rollers, and replace any missing idlers.

- Check and Adjust Idler Angle/Verticality: Use specialized tools to verify idler levelness and inclination angle, ensuring all idlers are coplanar and angles meet design specifications (especially the hexagonal angle in tubular sections).

- Routine Maintenance: Include idler inspection and maintenance in planned shutdowns, regularly replacing worn bearings or entire rollers.

Late-Stage Maintenance & Management Measures to Slow Collapse Deterioration

For older tubular belt conveyors experiencing declining stiffness and mild collapse that cannot be immediately replaced:

Refined Operational Management:

- Strict Load Control: Throughput must not exceed design capacity; avoid overload. For aged belts, recommended operation is at 80-90% of rated load.

- Reduce Operating Speed: Lower operating speed as much as possible while meeting production requirements to minimize dynamic impact and bending stress.

- Optimize Start/Stop: Use soft-start/soft-stop drives to reduce transient impact forces during starting and stopping cycles.

- Absolutely Avoid Empty Tube Running: Running empty or underloaded significantly reduces belt stability and accelerates collapse. Ensure adequate material fill rate during operation.

Enhanced Maintenance & Inspection:

- Shorten Inspection Intervals: Increase the frequency of inspections for belt condition (especially in collapsed or prone areas), idler status, and tension.

- Focus on Critical Areas: Prioritize inspections of convex curves, loading points, transition zones, and splice areas.

- Regular Debris Removal: Keep the return belt path and surrounding areas clean to prevent debris from being caught under the belt, causing idler jamming or belt scratching.

Environmental Protection:

- Improve Sun/Rain Shelter: Ensure the corrugated steel or rain shelter atop the truss is intact to minimize exposure to direct sunlight, rain, and windblown dust/sand.

- High-Temperature Protection: For hot materials, ensure ventilation and cooling measures are effective. Monitor actual belt surface temperature and avoid prolonged operation above recommended limits.

Develop Replacement Plan

Based on the belt's aging rate and collapse progression trend, formulate a detailed belt replacement plan early, prepare the budget, contact suppliers, and select an appropriate construction window.

Key Principles

- Safety First: All inspection and repair operations must be performed during downtime under Lockout-Tagout (LOTO) conditions.

- Professional Assessment: Severe collapse incidents should prompt evaluation by the belt manufacturer or specialized tubular belt service providers to develop targeted solutions. Uninformed attempts can worsen the problem.

- Holistic Decision-Making: The choice of action must balance repair costs, downtime, remaining equipment lifespan, production criticality, and other factors. Temporary measures to sustain operation may be a stopgap, but ultimately, funding for systematic repair or renewal is necessary.